Description

No,Salt should not be applied to solar panels, as it can cause corrosion and reduce efficiency.

Understanding Solar Panel Corrosion Concerns

Solar panels’ corrosion is a significant concern for both installers and homeowners, especially in coastal regions. Salt in the air can cause a type of corrosion called salt fog corrosion, which, consequently, can weaken solar panels’ performance and lifespan. This part discusses specifically how salt affects solar panels and what features help resist this type of corrosion.

The Impact of Salt on Corrosion Rates

Salt, transferred by the ocean breeze, sits on the surface of solar panels and turns into an electrolyte that is vital for the electrochemical reaction to occur. These reactions lead to metals oxidizing, which is more commonly known as rusting. According to the National Renewable Energy Laboratory, the power output of solar panels in a salty environment degenerates

15% over a five-year period. By contrast, such a situation in a non-coastal area corresponds to merely

5%.

Features of Panels to Prevent Corrosion

Fortunately, manufacturers have managed to create specific features that help solar panels resist corrosion. For example, high-grade aluminum with a specification of

5052-H32 is used for processing a frame, as it provides the best resistance to salt water corrosion. Moreover, some manufacturers apply gloss coatings to the solar panels’ glass and backsheet, which prevent not only cracking but also, importantly, an additional salt retention barrier. Sea salt directly sits on the PERC layer of SunPower’s Maxeon solar panels, in which the element of aluminum is the most excellent protection against corrosion.

Why Is IEC 61701 Certification Important?

IEC 61701 certification is vital for the solar panels utilized in coastal regions. As mentioned, a solar panel with this certification was tested against a salt spray, demonstrating that it is resistant to corrosion for at least

1,000 hours using a

5% salt spray solution. Thus, this certification ensures that the product can withstand the harmful effects of the salt spray. For this reason, when purchasers select the solar panels with the IEC 61701 certification, they can be confident that their investment will be durable and immune to the corrosive impact of the salt.

How Does Salt Affect Efficiency?

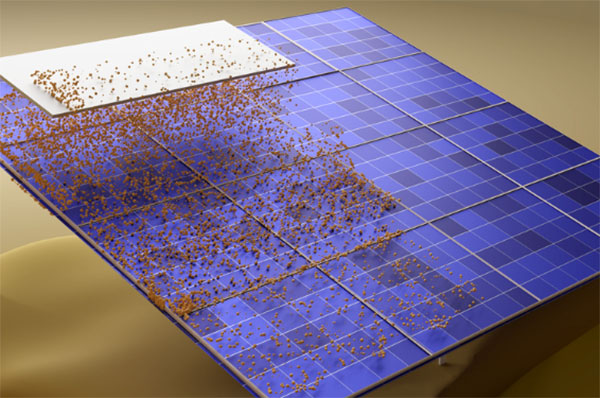

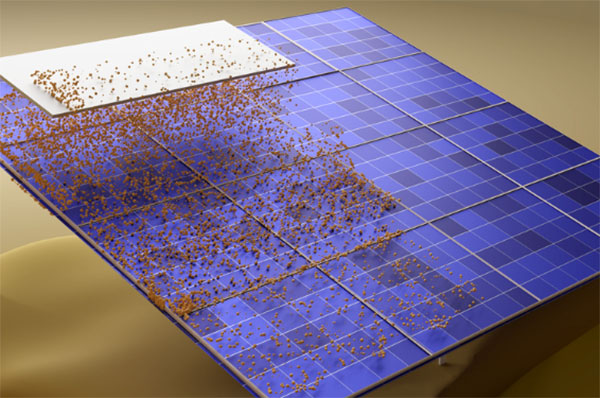

When the solar panels accumulate the salt from the air, it could significantly reduce their efficiency in both short-time and long-time values. This section explains the impacts of salt on the panels, ways to mitigate it, and warranty concerns.

Reduction in Efficiency

The loss of efficiency caused by the accumulation of salt on solar panels is not uniform but can be categorized as measurable and suitable for varying the panel’s electrical performance. According to Desert Research Institutes, the accumulation of a thin layer of salt on the surface of a solar panel reduced its efficiency by

5-10%. It happens because salt particles scatter the light, diverting it away from the photovoltaic cells and decreasing the amount of light received by these materials. Moreover, the salt is corrosive, and over time, it might etch the surface of the panels, destroying them, and causing efficiency reduction.

There are two ways to solve the problem of salt accumulation. Both the natural and the manual methods are used. Rainfall is expected to wash the problematic layer with salt away, which is the case, with issues. If the specific area is the arid coastal region, this solution will be ineffective. The amount of rain will never be sufficient to clean the solar panel. The manual cleaning is also better, as it’s more controlled. The professional cleaning service have water jet or soft brush to clean the salt of the panel with no harm to the texture. It is recommended that the solar panels in the high-salt environment are cleaned no less than once every three months to provide the best efficiency.

Warranty for Coastal Installation

Installation of solar panel in the coastal area should be closely monitored with the regard to the warranty. Not every warranty covers the specific case, and the branches on the coastal side are actively damaged by the salt. The choice of solar panel should be decisively limited to the variants, which bear the warranty that strictly covers the salt-induced corrosion and degradation issues. For example, the aforementioned high-end solar panel producers’ warranty covers all the cases of performance degradation due to salt. Homeowners should proceed with installations only after the readiness of these details.

High-Grade Panels and Their Anti-Corrosion Properties

One of the benefits of high-grade solar panels is that they are specifically designed to resist the corrosive influence of coastal environments. Often, these panels feature a frame made of anodized aluminum or stainless steel, which was selected for its saltwater corrosion resistance. High-grade panels can undergo exposure to the salt for decades, and they will not be degraded. Moreover, the modern high-grade panels might include a high-transparency backsheet that prevents salt particles from getting into the panel, thus eliminating corrosion risk and allowing the panel to be productive.

Solar Technology Application and Longevity

Correct solar technology application is especially important for the coastal region. Modern solar panels might be made with Maxeon or PERC technology, specifically made to ensure longevity under various conditions. The Australian National University investigated various types of solar technology and came to the conclusion that solar panels featuring PERC technology indeed lasted longer. The reason for such appeal was that those panels had an additional back passivation layer that not only increased efficiency but also protected panels from the environment. The degradation of PERC panels in the coastal environment was

0.25% a year, while the conventional panels were degraded at

0.45% each year.

Comprehensive Warranty Protection

Finally, comprehensive warranties are essential for panels used in the coastal regions to serve as an insurance against the costly damage due to an adverse environment. The best warranties are those that cover their performance, the materials used, and the work performed. They should last at least

10 years, but the most reliable ones may last up to

25 years. Before purchasing, however, the fine print should be read to check whether the warranty covers corrosion and salt damage defence. Getting a good warranty ensures that an investment is protected, and a buyer will not regret their purchase.

The Effects of Sea Conditions on Solar Performance

Solar panels installed in marine environments face unique challenges due to the sea conditions. This section will discuss how the marine climate impacts the output of solar panels, the interaction between saltwater and the panels, and the long-term considerations for photovoltaic systems installed in such settings.

Influence of Marine Climate on Panel Output

The marine climate, characterized by high humidity and salt-laden air, can significantly affect the performance of solar panels. According to a study published in the Renewable Energy journal, solar panels in coastal areas incurred a

20% reduction in output power because of the combined effect of humidity and salt deposit. This occurs mainly because the moisture and salt leave deposition on the surface of the solar panel, thereby making it less efficient to absorb light and lessen the ability of the panel to convert sunlight into electricity.

Dynamic Interaction Between Saltwater and Panels

The interaction between saltwater and solar panels is a crucial phenomenon that initiates the degradation process. The saltwater spray deposited on the surface of the panels causes electrochemical reactions, which corrode the metal in the solar panels. According to a study conducted by the University of California, San Diego, saltwater corrosion reduces the lifespan of solar in marine locations by up to

30%. Therefore, it is important to use solar panels having robust corrosion-resistant concerns and coatings to reduce this effect.

Long-Term Aspects of PV Systems Installation in Marine

Due to the peculiarities of a marine environment, long-term aspects of installing PV systems in such an area should be taken into consideration. The choice of materials, the way of structuring, and the scheme of maintenance processes matter. For instance, resistance to salt water can be provided by constructing the mounting structure of marine-grade stainless steel. Such a system requires regular maintenance, i.e., periodical cleaning of PV panels, and monitoring the state of the panels and mounting hardware. Therefore, these measures allow addressing the long-term aspects of operation, as installed PV systems are able to function efficiently during a considerable period of time.