Description

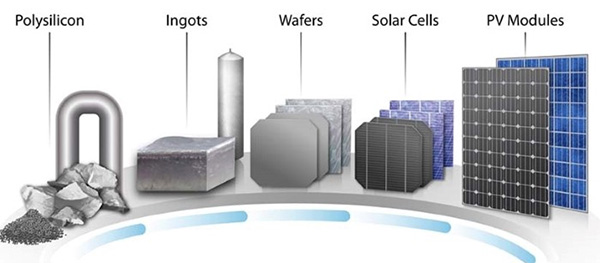

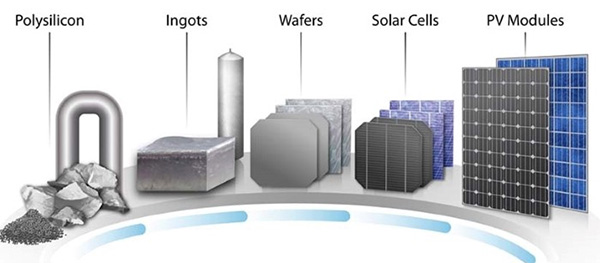

Polysilicon serves as a foundational material in the solar industry for making solar cells, integral components of solar panels. It is crucial due to its high purity and semiconductive properties, enabling efficient conversion of sunlight into electricity, facilitating the generation of renewable energy in photovoltaic systems.

Production of Polysilicon

Polysilicon production is an intricate process that primarily involves the refinement and processing of raw silicon to form a pure and crystalline structure, vital for various applications, notably in the solar industry. Its extensive use in solar panels attributes to its high purity level, typically over 99.9999%, necessary for the efficient conversion of sunlight into electricity.

Raw Material: Silicon

Silicon is a fundamental raw material in the production of polysilicon. Extracted mainly from sand, silicon is the second most abundant element in the earth’s crust. It is found in nature in the form of silicon dioxide (SiO2), and extensive refining processes are needed to extract pure silicon suitable for polysilicon production.

The extraction process begins with mining quartz, a common mineral composed of silicon dioxide. Subsequent steps involve reducing silicon dioxide to silicon metal, usually using carbon in a high-temperature furnace. After obtaining silicon metal, further refining is necessary to achieve the purity level required for polysilicon production.

Manufacturing Process

The manufacturing process of polysilicon involves chemical vapor deposition (CVD). In this crucial step, purified silicon deposits on a substrate to form polysilicon rods. The Siemens process, a prevalent method at this stage, facilitates a reaction between silicon tetrachloride (SiCl4) and hydrogen (H2), resulting in the creation of polysilicon and hydrochloric acid (HCl).

In the

Chemical Vapor Deposition (CVD) process, gases react at high temperatures, resulting in the deposition of a thin film of pure polysilicon on the substrate. This method is renowned for producing high-purity and high-quality polysilicon.

Purification of Polysilicon

Purification is paramount in achieving the high purity levels of polysilicon required for photovoltaic applications. The processed polysilicon undergoes multiple purification steps to remove any impurities and attain the desired purity level.

Advanced refining techniques break down the polysilicon rods obtained from the CVD process into chunks. These chunks undergo further refinement and turn into solar-grade polysilicon, which then serves as the primary material in manufacturing solar cells for photovoltaic systems, thereby guaranteeing optimal performance and efficiency in converting energy.

This detailed overview provides insights into the meticulous processes involved in the production of polysilicon, highlighting the importance of each stage in achieving the superior quality required for solar applications.

Polysilicon in Solar Cells

Polysilicon is pivotal in the solar industry, serving as a fundamental element in creating

photovoltaic cells, the essential units of solar panels. The high purity and crystalline structure of polysilicon make it optimal for converting sunlight into electricity efficiently.

Role of Polysilicon in Photovoltaic Cells

In photovoltaic cells, polysilicon plays an indispensable role, influencing the efficiency and performance of solar cells significantly. It functions as a semiconductor, absorbing sunlight and enabling electricity generation through the photovoltaic effect. The exceptional purity of polysilicon ensures a smooth electron flow, reducing energy loss and optimizing electricity production.

Conversion efficiency in solar cells signifies the capability to transform sunlight into utilizable electricity. The intrinsic properties of polysilicon, such as its crystalline structure and purity, facilitate higher conversion efficiencies, establishing it as a preferred material in the solar sector.

Types of Solar Cells Using Polysilicon

Polysilicon finds its application in various types of solar cells, each possessing distinct characteristics and uses, mainly in monocrystalline and multicrystalline solar cells. The distinguishing factor between these cells is the crystal structure.

Monocrystalline Solar Cells

Monocrystalline cells are derived from single-crystal silicon, resulting in a more uniform and sleek appearance. They exhibit higher efficiency and save more space due to their elevated energy output per square foot, albeit at a higher production cost compared to multicrystalline cells.

With their high efficiency and sleek aesthetics, monocrystalline solar cells are a great fit for spaces with limitations, such as residential rooftops, owing to their compact size and high power output.

Multicrystalline Solar Cells

Conversely, multicrystalline solar cells consist of multiple crystal structures, exhibiting a textured and granulated appearance. Their production cost is lower, but they typically offer less efficiency compared to monocrystalline cells.

The affordability and versatility of multicrystalline cells make them a favored option in a range of applications, including large solar farms and residential installations, particularly where budget considerations take precedence over the pursuit of maximum efficiency.

By delving into the multifaceted roles and applications of polysilicon in solar cells, its invaluable contribution to the progression of solar technology and its influence on creating sustainable energy solutions becomes evident.

Benefits of Using Polysilicon in Solar Technology

Polysilicon is renowned for the myriad of benefits it offers in solar technology. The high-quality, durable, and efficient nature of polysilicon has made it the material of choice in the manufacture of photovoltaic cells, driving advancements in sustainable energy solutions.

Efficiency and Performance

Polysilicon stands out for its exceptional efficiency and performance in converting sunlight into electricity. Its crystalline structure and high purity level ensure minimal energy loss during the conversion process, optimizing the performance of solar panels.

Polysilicon-based solar cells exhibit superior conversion efficiencies, typically ranging from 15% to 22%. This high efficiency means that polysilicon solar panels can generate more electricity per unit area compared to other materials, making them a preferred choice for space-constrained installations.

Durability and Reliability

Polysilicon’s inherent durability and stability underpin its reliability in long-term solar applications. Solar panels made from polysilicon are known to have long lifespans, often exceeding 25 years, with minimal degradation in performance over time.

The long-term stability of polysilicon ensures consistent energy output and minimal maintenance requirements throughout the operational life of the solar panels. This long-lasting reliability has contributed to the widespread adoption of polysilicon in various solar applications.

Sustainability and Environmental Impact

The use of polysilicon in solar technology underscores a commitment to sustainability and environmental preservation. Solar panels using polysilicon contribute to the reduction of greenhouse gas emissions by generating clean and renewable energy.

By utilizing polysilicon-based solar panels, we can harness eco-friendly energy solutions that mitigate climate change and promote environmental conservation. The production of electricity through polysilicon solar panels significantly reduces the reliance on fossil fuels, curbing carbon emissions and fostering a sustainable energy future.

Product Recommendation: Tongwei

Tongwei is a recognized leader in the polysilicon industry, renowned for producing high-quality polysilicon products. The company’s polysilicon is distinguished by its high purity and superior performance, making it ideal for the production of efficient and reliable solar panels.

Why Choose Tongwei?

Opting for Tongwei’s polysilicon products ensures access to top-tier materials characterized by enhanced durability, efficiency, and environmental compatibility. Tongwei’s commitment to innovation and quality makes their polysilicon products a preferred choice for those seeking to leverage the benefits of advanced solar technology.

The incorporation of polysilicon in solar technology brings forth a spectrum of benefits, from enhanced efficiency and performance to long-term reliability and sustainability, paving the way for a cleaner and greener future.

Challenges in Polysilicon Production and Usage

While polysilicon is crucial for the production of photovoltaic cells in solar panels, the production and usage of polysilicon are not without challenges. The production cost, environmental impact, and the balancing act between market demand and supply are among the significant challenges facing polysilicon production and utilization.

High Production Cost

The production of polysilicon is an energy-intensive process, involving sophisticated technologies and extensive purification procedures to achieve the desired levels of purity. The associated high production costs can be a limiting factor in the widespread adoption of polysilicon in solar technology.

The search for cost-effective alternatives is an ongoing endeavor in the solar industry. While polysilicon remains a predominant material due to its high efficiency, the exploration of cheaper and equally efficient materials is crucial to making solar technology more accessible and affordable.

Environmental Concerns in Polysilicon Manufacturing

The manufacturing process of polysilicon raises environmental concerns due to the use of hazardous chemicals and substantial energy consumption. Managing the environmental footprint of polysilicon production is crucial to aligning the solar industry with sustainable practices.

Implementing sustainable production practices and utilizing green technologies are imperative to minimize the environmental impact of polysilicon manufacturing. Addressing the environmental challenges in

polysilicon production is essential to maintaining the ecological integrity of solar technology.

Market Demand and Supply Issues

The fluctuating market demand and supply dynamics of polysilicon can create challenges in maintaining production equilibrium. Variabilities in demand can lead to price volatilities, impacting the cost-effectiveness of polysilicon-based solar solutions.

Striking a balance between the production and demand of polysilicon is vital to stabilizing prices and ensuring the steady availability of polysilicon for solar applications. Addressing market imbalances is crucial to fostering a conducive environment for the growth and development of polysilicon-based solar technology.

The challenges in polysilicon production and usage underscore the need for innovative solutions, sustainable practices, and balanced market dynamics to realize the full potential of polysilicon in advancing solar technology. Overcoming these challenges is pivotal to leveraging the benefits of polysilicon in fostering a sustainable energy future.

Market and Economic Impact

The polysilicon market and its economic repercussions are pivotal aspects of the solar industry, affecting stakeholders ranging from manufacturers to end-users. Global market dynamics, industry players, and economic ramifications actively shape the development and acceptance of polysilicon-based solar technologies.

Global Polysilicon Market Analysis

Analyzing the global polysilicon market provides insights into the trends, growth, and challenges shaping the industry. The polysilicon market is influenced by multiple factors including demand and supply dynamics, price fluctuations, and technological advancements in polysilicon production.

The polysilicon market has been experiencing substantial growth, propelled by the escalating demand for clean and renewable energy sources. This growth trajectory is anticipated to persist, with increasing investments in solar energy projects and advancements in polysilicon production technologies fueling market expansion.

Key Players in the Polysilicon Industry

The polysilicon industry is characterized by the presence of several key players, each contributing to the development and supply of high-quality polysilicon. Companies like

Wacker Chemie and

OCI Company are notable entities driving innovations and production in the polysilicon sector.

The key players in the polysilicon industry play a significant role in shaping market dynamics and technological advancements. Their commitment to research and development, production scale, and market strategies influence the availability, quality, and pricing of polysilicon, impacting the overall solar industry landscape.

Economic Impact of Polysilicon in Solar Industry

The economic ramifications of polysilicon are substantial, influencing the cost-competitiveness and economic viability of solar energy solutions. The economic implications extend beyond the production costs, affecting job creation, investment opportunities, and the overall economic growth of regions involved in polysilicon production and utilization.

The polysilicon industry is a crucial job creator, offering employment opportunities in production, research, and development sectors. The investments flowing into the polysilicon sector stimulate economic activity, contributing to the financial prosperity and development of regions engaged in polysilicon-related activities.

Understanding the market dynamics, acknowledging the roles of key industry players, and assessing the economic impacts are essential in comprehending the influence of polysilicon in the solar industry. These elements collectively shape the future prospects and sustainability of polysilicon-based solar technologies, impacting global renewable energy endeavors.