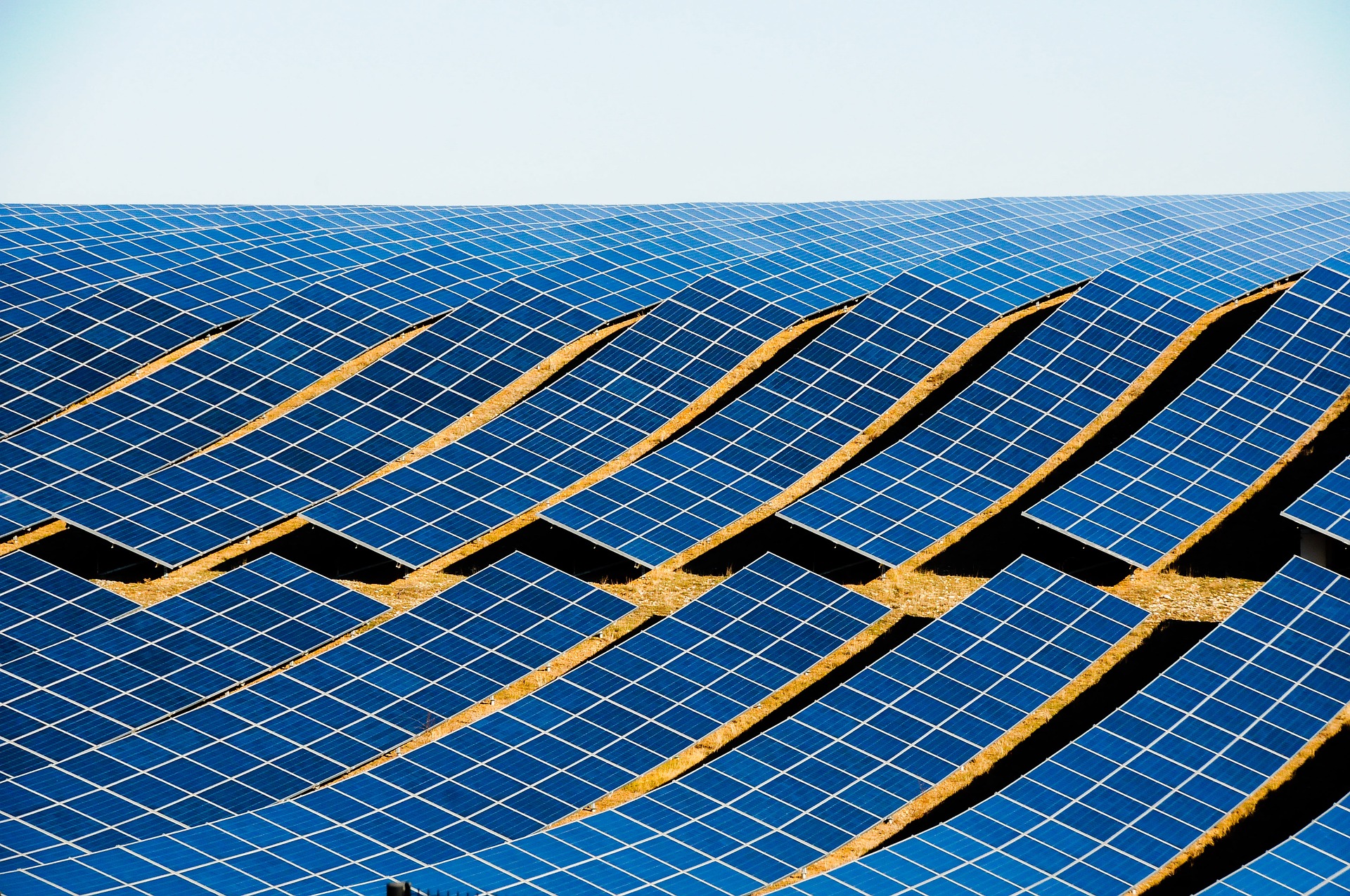

Polycrystalline solar modules are common choices for tapping solar energy due to their affordability and consistent supply. Technically speaking, from the photovoltaic cells, AC and DC power conversion, to the overall energy output, they are second to none in this field of renewable energy.

Poly Solar Module Efficiency: How Photovoltaic Cells Come into Play

Polycrystalline solar modules are built with many silicon crystals, making them different in structure compared to other types and thus directly influencing efficiency. On average, the efficiency of poly solar modules lies between 15% and 17%, which is a bit lower than that of monocrystalline modules. However, this results in lower module pricing. For example, using a standard 300W poly module with 16% efficiency could generate about 450 kWh of electricity in a year under optimal conditions. That makes them suitable for residential and commercial applications where cost is a critical factor. Besides, recent developments in cell technology, like PERC, have pushed the efficiency of poly modules closer to 19%, narrowing the gap with their monocrystalline counterparts.

For economic considerations, poly solar modules enable quicker ROI with a lower cost per watt. For example, the average installation cost of a 5 kW poly solar system in the United States is $10,000, while that of a similar monocrystalline system is $12,500. This 20% cost reduction, with adequate efficiency, makes poly modules an economically viable option for both large-scale solar farms and rooftop installations.

Conversion of Solar Energy: The Dynamics between AC and DC Power in Poly Modules

Solar modules produce DC power that needs to be converted into AC for most households and commercial facilities. Poly solar modules are highly compatible with modern inverters featuring high-efficiency DC-to-AC conversion. For example, a typical inverter with 95% efficiency can convert the DC output from a poly module into usable AC power with very minimal losses. This conversion efficiency is very important because any small loss percentage can considerably impact the overall energy output a solar system may have over its 25-year lifespan.

To put that in perspective, if a poly solar system produces 5,000 kWh of DC electricity in a year, an inverter that is 95% efficient will convert this to 4,750 kWh of usable AC electricity. That is equivalent to saving about $712 annually, assuming an average electricity cost of $0.15 per kWh. By contrast, an inverter with an efficiency of only 90% would convert that same DC output to only 4,500 kWh of AC—a reduction in annual savings of $37. Over the course of 25 years, that 5% difference in inverter efficiency could amount to almost $1,000 in lost savings.

Longevity and Durability: The Structural Strength of Poly Solar Modules

In general, poly solar modules are of high quality and can easily withstand extreme environmental conditions, such as very high temperatures, humidity, and mechanical stress. The standard annual degradation rate is approximately 0.5% for a normal poly module, which means that after 25 years, it would still retain about 87.5% of its original efficiency. For example, a 250W poly module installed in a coastal area with high salt and humidity exposure will still produce approximately 219W of power after 25 years, compared to 200W from modules with a 1% degradation rate.

Manufacturers also provide very durable warranties, often offering an 80% performance guarantee for up to 25 years. Long-term reliability is particularly important for large solar installations since the replacement or repair of separate modules takes a long time and is costly. With this, a 1 MW solar farm with poly modules can expect to lose only 50 kW in capacity over 25 years due to degradation, compared to 100 kW if the modules had a higher degradation rate. This lower degradation not only reduces the cost of maintenance but also ensures a far more stable energy output over the life of the project.

Economic Impact: Cost-Effectiveness of Poly Solar Modules for Large-Scale Projects

Poly solar modules have relatively lower upfront costs compared to other types of modules. A 10 MW solar farm, for instance, can save up to 15% in terms of the initial investment cost in modules by using poly modules instead of monocrystalline modules. Assuming the cost of the monocrystalline modules is $0.30/watt, the total module cost for a 10 MW solar farm will be $3 million. In such a case, choosing the poly modules priced at $0.25/watt, the initial cost saving for the project will be $500,000.

This saving is even higher when scaled up to utility-scale projects. For instance, a 100 MW solar farm using poly modules will realize savings upwards of $5 million in module costs alone. Such savings can, therefore, be used for other project aspects to enhance further performance or profitability, such as advanced tracking systems or high-efficiency inverters.

Eco-Friendly Advantage: Poly Solar Modules Lower Carbon Emission

Poly solar modules contribute significantly to reducing carbon emissions. It is estimated that approximately 0.5 kg of CO₂ emissions are avoided in generating every 1 kWh of electricity through a poly solar module when compared to coal-fired power generation. A 5 kW poly solar system can generate approximately 6,000 kWh annually, saving 3,000 kg of CO₂ emissions every year. Over a 25-year lifetime, this equates to a total saving of 75,000 kg of CO₂, equivalent to planting approximately 3,500 trees.

The energy payback time for poly modules—the time required for the module to produce the amount of energy that was used in its manufacture—is about 2-3 years. This means that beyond this period, the module continues to generate clean energy with a net positive impact on the environment. For instance, a 1 MW poly farm would offset about 500 metric tons of CO₂ equivalent every year, which makes it a very strong tool in fighting climate change and fostering sustainable energy use practices.