Description

The main components of a solar cell include the semiconductor material (often silicon), a p-n junction to create an electric field, anti-reflective coating to maximize sunlight absorption, a metal conductive grid to transport electrons, and encapsulant and backsheet for protection and insulation.

Basic Structure of a Solar Cell

The basic

structure of a solar cell encompasses layers and materials designed to capture

sunlight, transform it into electrical energy through the photovoltaic effect,

and then transport the generated electricity.

The Photovoltaic Effect

The

photovoltaic effect is the phenomenon that allows solar cells to convert

sunlight into electricity. It's the fundamental principle that enables the

functioning of photovoltaic cells. Here's a detailed look at what happens:

- Absorption of Light: When sunlight strikes the solar

cell, photons from the light can transfer energy to electrons in the atoms

of the semiconductor material.

- Creation of Electron-Hole Pairs: This transferred energy knocks

electrons loose from their atoms, allowing them to flow freely within the

material.

- Generation of Electric Current: These free electrons then move

through the material to produce an electric current. They get collected by

conductive metal contacts on the top and bottom of the cell and can be

drawn off as electricity to power anything from a small appliance to a

whole house.

- Importance in Solar Technology: The photovoltaic effect is the basis for solar power, and understanding this phenomenon is key to developing more efficient solar energy technologies.

Layers of a Solar Cell

Solar cells

consist of several layers, each with a specific function in converting sunlight

into electrical energy. The primary layers include:

- N-Type Semiconductor Layer: Contains impurities that add

excess electrons, giving it a negative charge.Forms one side of the p-n junction,

vital for energy conversion in the cell.

- P-Type Semiconductor Layer: In contrast to the N-Type layer,

this layer has a doping process to reduce the number of electrons,

resulting in a positive charge.It forms the other side of the p-n

junction, balancing the energy conversion process.

- Antireflection Coating: This layer helps the cell to

capture more sunlight by reducing reflections.

- Conductive Grid: A network of thin metal fingers

that collects the electrons and sends them to an external circuit.

- Back Sheet and Encapsulation: These provide protection and

insulation for the cell.

These layers work together, allowing the cell to absorb sunlight and efficiently convert it into electricity. The structure of a solar cell is an intricate design that balances efficiency, durability, and cost, and ongoing research in materials and design continues to drive advancements in solar energy technology.

Main Components

Earlier, we

discussed the main components of the system, which include Semiconductor

Material such as Silicon-based Cells and Thin-film Technology, the P-N

Junction, Anti-Reflective Coating, the Metal Conductive Grid, the Encapsulant,

and the Backsheet.

Semiconductor Material

Semiconductor

materials are at the core of solar cells, enabling the conversion of sunlight

into electricity. The main types include:

Silicon-based Cells

These are

the most common types of solar cells, made primarily from silicon, a widely

available and affordable material. There are two main types:

- Monocrystalline Cells: Composed of a single crystal

structure, they offer high efficiency and a sleek appearance but usually

come at a higher cost.

- Polycrystalline Cells: Made from multiple crystal

structures, they are generally less expensive but also less efficient.

Thin-film Technology

Thin-film solar cells are made by depositing one or more thin layers of photovoltaic material on a substrate. They are lighter and more flexible but usually less efficient than silicon-based cells.

P-N Junction

The p-n

junction is a critical component in a solar cell, formed by p-type (positive)

and n-type (negative) semiconductor materials. It's the region where the conversion

of sunlight into electricity occurs:

- Function: It allows the flow of electric

current in one direction and blocks it in the other, facilitating the

movement of electrons from the n-type to the p-type.

- Importance: The design and quality of the p-n

junction affect the cell's efficiency in converting sunlight into usable

electric power.

Anti-Reflective Coating

The

anti-reflective coating is applied to the top surface of the solar cell:

- Purpose: It reduces the reflection of

sunlight, allowing more light to enter the cell, thus increasing

efficiency.

- Benefits: By capturing more sunlight, the

coating helps in maximizing the cell's energy conversion capability.

Metal Conductive Grid

Located at

the top of the solar cell, the metal conductive grid has vital roles:

- Function: It collects the free electrons

generated in the semiconductor and channels them into an external circuit,

converting them into usable electricity.

- Design Consideration: The grid must be designed to

collect maximum current without obstructing too much sunlight from

reaching the semiconductor material.

Encapsulant and Backsheet

These

components provide the final layers of a solar cell:

- Encapsulant: A clear compound that encapsulates

the solar cell, providing protection without interfering with its optical

or electrical properties.

- Backsheet: The outermost layer of the solar

cell, providing structural support and protecting the internal components

from environmental damage.

Together, these main components form a complex system that converts sunlight into electricity. Understanding each part's role and characteristics helps in designing more efficient and cost-effective solar energy solutions.

Types of Solar Cells

We covered

this section earlier, outlining the main types of solar cells: Monocrystalline,

Polycrystalline, Thin-Film, and Multi-Junction, each with its unique

advantages.

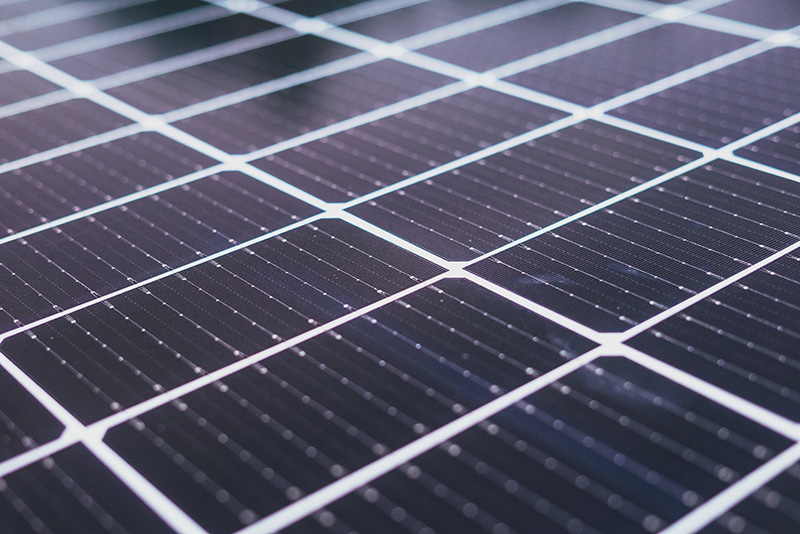

Monocrystalline Solar Cells

Monocrystalline

solar cells are made from a single crystal structure, giving them a distinctive

uniform appearance.

- Advantages:

- High efficiency due to the purity

of the crystal structure.

- Long lifespan and durability.

- Aesthetic appearance.

- Applications: Residential and

commercial installations with limited space and a desire for high

efficiency are ideal for these products.

- Recommendation: Companies such as

TongWei provide monocrystalline solar cells known for high performance and

reliability.

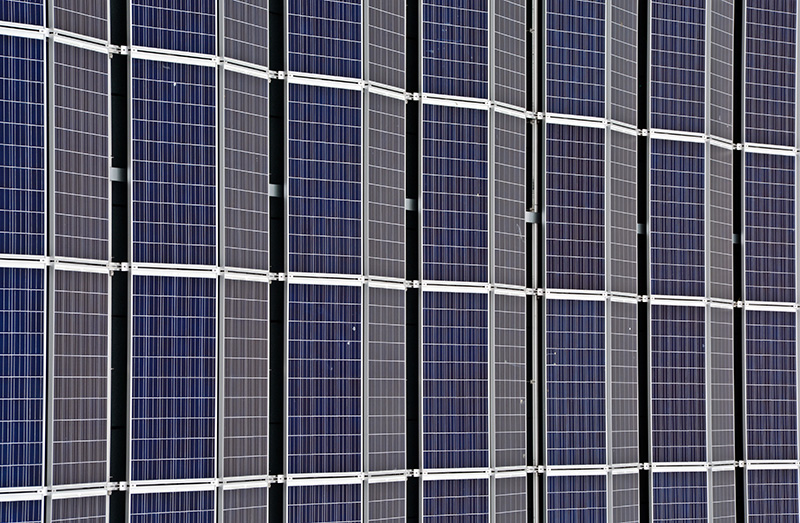

Polycrystalline Solar Cells

Polycrystalline

solar cells are made from multiple crystal structures, recognizable by their

speckled blue appearance.

- Advantages:

- Generally less expensive than

monocrystalline cells.

- Slightly lower efficiency but

offers good value for money.

- Suitable for various applications.

- Applications: Often used in larger installations

where cost-effectiveness is a priority.

- Recommendation: TongWei's solar cells include

options in the polycrystalline range, providing an economical choice

without compromising on quality.

Thin-Film Solar Cells

Thin-film

solar cells are created by depositing thin layers of photovoltaic material on a

substrate.

- Advantages:

- Lightweight and flexible.

- Can be integrated into building

materials.

- Lower cost compared to crystalline

cells but also lower efficiency.

- Applications: Suitable for large-scale

installations or places where flexibility and weight are considerations.

- Recommendation: While not specifically offered by

TongWei, many reputable manufacturers specialize in thin-film solar

cells.

Multi-Junction Solar Cells

Multi-junction

solar cells contain multiple p-n junctions, each designed to absorb a different

part of the solar spectrum.

- Advantages:

- Extremely high efficiency by

utilizing a broader range of the sunlight.

- Often used in space and specialized

applications.

- Cutting-edge technology that pushes

the boundaries of solar energy conversion.

- Applications: Primarily found in research,

space, and other high-tech applications.

In summary, the diverse types of solar cells cater to different needs and applications. With advancements in technology and manufacturing, companies like TongWei are leading the way in offering a wide range of solar cell options, from the highly efficient monocrystalline cells to the more economical polycrystalline options. Choosing the right type depends on individual requirements, budget, and the specific application.

Performance Factors

Understanding

the performance factors of solar cells is crucial for selecting the right

technology for specific needs and environments. Key factors include efficiency,

temperature coefficients, and longevity and degradation.

Efficiency

Efficiency

refers to the percentage of sunlight that a solar cell can convert into usable

electrical energy. Here's how it varies among different types:

- Monocrystalline Cells: Typically, around 15% to 20%, with

some advanced models reaching up to 22%.

- Polycrystalline Cells: Generally, ranges from 13% to 16%.

- Thin-Film Cells: Around 10% to 12%.

- Multi-Junction Cells: Can reach efficiencies over 40%,

particularly in specialized applications.

Higher

efficiency means more energy production for a given area, making it a critical

consideration for places with limited space.

Temperature Coefficients

The

temperature coefficient is a measure of how the efficiency of a solar cell

decreases with rising temperature. For most crystalline silicon-based cells,

the coefficient is usually around -0.3% to -0.5% per degree Celsius. This means

that for every degree increase in temperature above 25°C, the efficiency drops

by that percentage.

- Importance: In hot climates, the temperature

coefficient can significantly affect the solar cell's performance, so

selecting a cell with a lower coefficient may be beneficial.

- Variation: Different materials and designs

may have varying temperature coefficients, and this aspect should be

considered based on the local climate and installation conditions.

Longevity and Degradation

Solar cells

gradually degrade over time, affecting their performance. The typical numbers

are:

- Longevity: Most solar cells come with a

lifespan of 25 to 30 years, although they can often continue to function

beyond that at reduced efficiency.

- Degradation Rate: On average, solar cells degrade at

a rate of about 0.5% to 1% per year. Some high-quality models, like those

from renowned manufacturers, may have even lower degradation rates.

- Warranty Considerations: Many manufacturers offer

warranties that guarantee a certain level of performance after a specific

number of years, typically around 80% after 25 years.

These performance factors provide a comprehensive view of what to expect from solar cells over their operational life. By understanding efficiency, temperature coefficients, and longevity and degradation, users can make informed decisions that match their specific needs and environmental conditions. Whether seeking high efficiency or long-term reliability, understanding these factors ensures a more sustainable and effective solar energy solution.

Manufacturing Process

The

manufacturing process of solar cells is complex and involves several key

stages. Here's a detailed overview of each step:

Purification of Silicon

Silicon is

the primary material used in most solar cells. However, it needs to be purified

before it can be used.

- Raw Material: Silicon is extracted from silica

sand.

- Purification Process: It involves multiple steps,

including refining, reduction, and zone melting to achieve the necessary

purity level, usually 99.9999%.

- Result: The purified silicon is the

fundamental building block for creating solar cells.

Ingot Casting

The next

stage is forming the purified silicon into ingots.

- Melting: Technicians melt the silicon in a

crucible at temperatures exceeding 1400°C.

- Casting: They then cast the molten silicon

into ingots using techniques like the Czochralski growth method or the

Bridgman process.

- Cooling: They cool the ingots slowly to

create a crystalline structure, which can be either monocrystalline or

polycrystalline, based on the method applied.

Wafer Slicing

Ingots are

then sliced into thin wafers, which become the substrate for the solar cells.

- Sawing: Operators use precision saws

to cut the ingots into thin wafers, generally around 200 micrometers

thick.

- Polishing: They then polish the

wafers to smooth the surface and prepare them for further processing.

Cell Production

The wafers

undergo several processing steps to become functioning solar cells.

- Doping: Introducing impurities into the

silicon wafers to create the required p-n junction.

- Etching: Removing any impurities or defects

from the surface.

- Coating: Applying anti-reflective coatings

to maximize sunlight absorption.

- Printing: Adding the metal conductive grid

for electron collection.

Module Assembly

The final stage

involves assembling the individual cells into solar modules or panels.

- Arrangement: Workers arrange the specific

pattern of cells, often connecting them in series, to achieve the required

voltage.

- Lamination: Protective materials like glass

and polymers encapsulate the cells.

- Framing:Typically, aluminum frames the

laminated module to provide structural support and aid in mounting.

- Testing and Inspection:Technicians conduct tests on the

completed module to evaluate performance, and perform quality inspections

before shipping.

The entire manufacturing

process for solar cells is a blend of high-tech engineering and precise

craftsmanship. From the initial purification of silicon to the final assembly

of the modules, each step must be meticulously executed to create a product

capable of converting sunlight into electricity efficiently and reliably.

Manufacturers continuously innovate to make this process more sustainable and

cost-effective, contributing to the growing accessibility of solar energy

worldwide.