Introduction

Silicon, being the second most abundant element in the Earth’s crust, plays a crucial part in the photovoltaic industry. The properties of silicon make it an ideal material for converting the energy of the sun into electricity. More to the point, while the current definitions shed some light on the characteristics of silicon, they still do not provide any specific facts concerning the role of silicon in solar power generation, the availability of silicon or the purposes that recycling serves in the solar power industry. This is the sort of information that the following answers will offer.

The role of silicon in PV

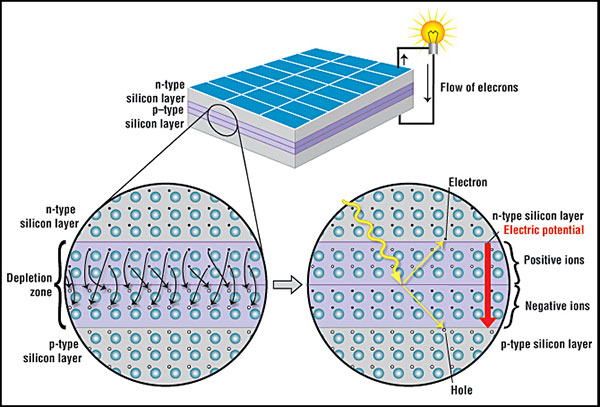

The current version of the definition of silicon’s role in the creation of solar panels, though detailed, is too complicated: “Every solar panel has at its heart a semiconductor material that can efficiently absorb sunlight, extract electrons and electrically push these out of the solar panel to create electricity. In the photovoltaic industry, silicon is the semiconducting material primarily used in the production of solar cells.”

Silicon availability

Recycling: purposes and challenges

While the information used during the previous modules’ exercise can be considered as accurate and relevant, it is not always concise. However, where the current facts are concerned, the message gains a clear, unequivocal tone. The definitions of silicon’s role in the creation of solar panels, its purpose in PV, and the purposes of recycling in the solar power area all offer specific and detailed information on each topic.

Responsible Sourcing

The solar industry is becoming increasingly concerned with responsible sourcing and manufacturing practices. This ensures the long-term availability of silicon and drives the investors to continually develop the technologies reducing the energy consumption, and environmental impact of silicon production.

The Recycling Initiative

The recycling of silicon solar panels is vital in the sphere of solar power, as it enables to minimize ecological footprint instead of continuously produce the material. In line with current practices, the existing recycling methods allow for recovering over 90% of the silicon material from the end-of-life panels.

The Future of Silicon in Solar Power

As the world is shifting towards sustainable energy solutions, the importance of silicon in solar power generation will grow. The improvements in silicon-based solar cell technology will add to the developments in the performance efficiency and cost. With current recycling initiatives and responsible sourcing, it may not seem far-fetched that the solar industry will provide the generations to come with a sustainable supply of silicon. This will be a significant contribution towards the future of renewable energy and the struggle against climate changes.

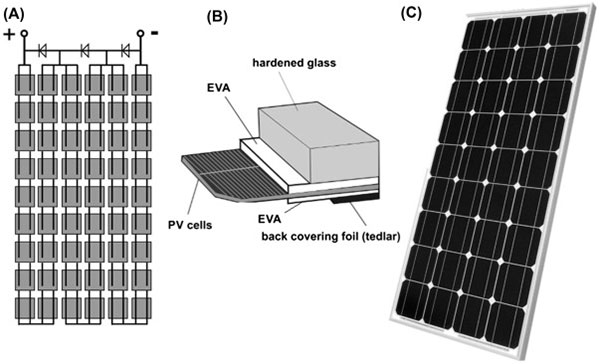

Understanding the Weight of Silicon in Solar Panels

Solar panels come in various values and sizes, and the weight of the silicon they are composed in is a vital factor in the design, installation, and overall performance of photovoltaic solar energy systems. In this section, we will analyze the silicon content in 1 kW solar panel batteries and tentatively estimate the silicon content of each that we are going to look into.

Silicon Content in 1 kW Solar Panel Units

One of the major factors that need to be considered when examining the silicon content in a 1 kW solar panel unit is the type of unit, as well as its efficiency. For example, a typical high-efficiency unit comprised of monocrystalline silicon will typically weigh about 19 kg, while a similar polycrystalline unit will weigh between 21 and 23 kg. The difference in weight is due to the varying silicon cell structure and efficiency. In addition, the silicon content in both panels is closely tied to their power output. By definition, a unit comprised of highly efficient silicon panels will have lower silicon content per watt generated. The reason is that highly efficient panels, such as monocrystalline panels, can capture more sunlight across a given area.

Estimating Silicon Use in Modern Panels

Estimating the amount of silicon in the modern panels requires a decent understanding of the panel’s specifications, as well as the manufacturing process. Modern panels are typically optimized with a low thermal mass, striving to reduce the amount of silicon while also ensuring a sufficiently high power output. One of the newer production technologies ensures the use of thinner silicon wafers, allowing reductions in silicon content to be unaccompanied by reductions in efficiency. Moreover, about 2 micrometer, the thickness at which the silicon wafer is extremely sensitive to stresses, is lower than the thickness required for maintaining the chemical resistance properties of silicon. The use of passivation and anti-reflective coatings on the surface of the silicon cells can reduce the needed content of silicon by between 3 and 5 g/m^2 for silicon wafers with relatively low impurity concentration. Another innovation in silicon cell design, such as bifacial cells, improves efficiency by capturing sunlight from two sides, achieving the same output with less silicon.

The Future of Silicon in Solar Panels

Keeping in mind the liquid nature and fast pace of the solar industry’s development, the question of the future of silicon in developing solar panels is raised. Currently, materials such as perovskite and thin-film solar cells can be additional or even basic for silicon-based solar panels. However, silicon remains the primary material in such panels due to its proven track records, affordability, and abundance.

To sum up, being aware of the content of silicon in solar panels and its weight is critical to the development and installation of a solar power system. The industry should further consider future innovations and approaches to the effective use of materials. Eventually, it allows the industry’s goal to make solar energy a sustained, cheap source of power supply.

The Electrical Characteristics of Silicon Solar Cells

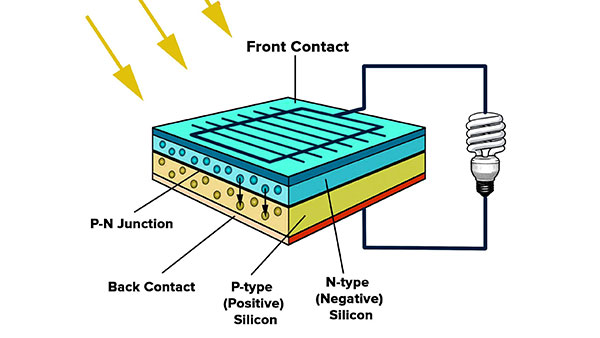

The main electrical characteristics of silicon solar cells that define their propriety include voltage, current, etc. These key elements assist in the proper hierarchy of cells in series and parallel. Such elements also define the power and necessity for voltage limits and circuit protection.

Voltage and Current in Individual Modules

Silicon and other photovoltaic cells work based on the photovoltaic effect. The current is generated as sunlight hits the cells by producing an electron flow. The best parameters defining an individual cell’s electrical propriety are open-circuit voltage and short-circuit current. Therefore, open-circuit voltage represents the voltage appearing between the terminals of a photovoltaic cell when no current flows. The suitable value for a standard silicon solar cell ranges from 0.5 to 0.6 volts. In addition, this value is influenced by the semiconductor material’s bandgap and temperature of the cell.

I_sc

The Short-Circuit Current of a photovoltaic cell that may deliver a current supply if a circuit becomes shorted, as detected in Fig.1. Such a current value is proportioned to a direct effect of the light degree falling on the photovoltaic cell. The current magnitude, or a reading device, fluctuates in relation to the sizes, materials, and selection features. Sometimes a short-circuit current of a monocrystalline silicon cell can achieve 5.5 amperes.

Arrangement and Parameters

It is possible to achieve a high value of either a current or a voltage of solar cells if they are connected. The connection itself is arranged as two ways: between two conventional lines or two different lines. Each connection method enables the manufacturers to improve or increase some parameters. Thus, all lines of electric force are to be fabricated so that they could stretch at the due v and v measure. When the solar battery is a single one, any accumulator battery may be suited.

Series Connection

An increased voltage value is achieved if the solar cells are set in series. Here the current value is unchanged, really the minimum but no less than short-circuited one. The connection is used for powering the batteries and the grid feeding. A 60 cell solar panel is a typical example of a series connection. If the open-circuit voltage measure of a single cell is consistent with its photo-diode characteristic, it is contingent that the total voltage of the arrangement is 36 volts (60 * 0.6). A current is determined by the sum of cell of the current, which is approximate to 5.5 amperes or a short-circuit current of the single cell.

To sum up, the electricity parameters of silicon solar cells, such as potential, current, and effect of series and parallel together, are critical in designing and perfecting solar energy systems. By taking these concepts into account, engineers are able to create and customize solar panel settings for various applications to best meet their needs and ensure that the renewable energy is used in an efficient manner.