Adhering to the principle of long-term cooperation and mutual growth with suppliers, we are building a green, sustainable, and digitalized supply chain system.

1. Supply Chain Sustainable Development Goals

In 2023, all primary raw material suppliers signed Social Responsibility Commitment and Integrity Commitment. Risk identification and on-site audits were initiated.

From 2024 to 2026, the company will complete risk identification and on-site audits of key raw material suppliers in stages, continuously building and optimizing the sustainable supply chain system.

2. Full life cycle ESG risk management

▶ Supplier Access: Fully integrate ESG into supplier screening assessment

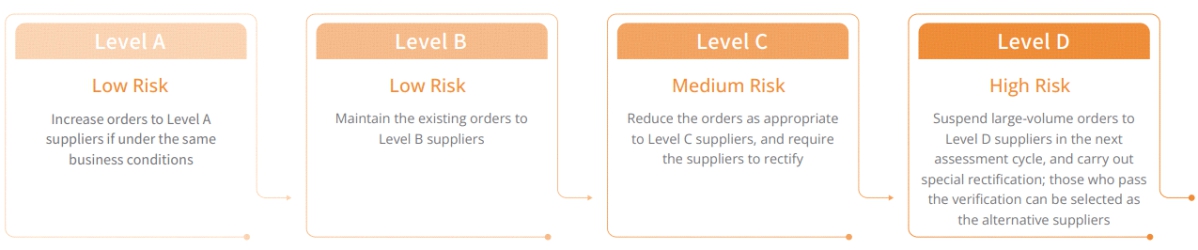

▶ Risk Management Matrix: Implement hierarchical management of existing supplier and conduct ESG investigation and monitoring according to risk level.

▶ Supplier Audit: Regularly conduct on-site supplier ESG audits, and suppliers are penalized and rewarded according to audit results.

▶ Supplier Exit: Require rectification for ESG audit findings, and the suppliers who fail to meet the requirements by the deadline will face penalties such as cessation of cooperation.

▶ Supplier Empowerment: Regularly conduct supplier ESG training and exchanges to empower the development of a sustainable supply chain system.

During supplier access screening and annual regular audits, we grade suppliers using Supplier EHS Audit Form and Supplier ESG Audit Form, evaluating their performance in areas

such as labor management, environmental protection, occupational health and safety, and business ethics. ESG factors such as labor management are evaluated alongside quality,

pricing, and other assessment criteria to determine supplier ratings and risk level assessment results.

If a supplier is involved in the following "zero-tolerance items " and poses significant potential risks, Tongwei reserves the right to terminate the new supplier introduction process

or to cease cooperation with suppliers already in the pool.

▶ Failure to obtain the necessary environmental permits

▶ Illegal discharge of air emissions, wastewater, or solid wastes

▶ Serious occupational health and safety problems

▶ Failure to obtain the necessary occupational health evaluation, safety evaluation, filing and acceptance

▶ Failure to obtain fire permits

▶ Child labor, discrimination, forced labor, etc.

▶ Failure to comply with the payment of employee salaries and benefits

▶ Use of forged or false documents

▶ Major breach of trust records

▶ Commercial bribery

▶ Unauthorized subcontracting

▶ Use or procurement of mineral resources from conflict areas

Supplier Audit

3. Responsible Procurement

(1)Labor Safety and Health:

We are dedicated to collaborating with our suppliers to establish a workplace characterized by dignity, ethical standards, safety, and health protection. We conduct targeted

assessments on critical issues such as child labor, forced labor, working hours, and labor safety and health. Through various channels, we assess the labor health and safety

conditions maintained by our suppliers to ensure strict adherence to labor rights and the provision of a safe working environment that aligns with established standards.

(2)Green and Low-Carbon Supply Chain:

Adhering to the concept of green development, we actively implement green procurement and promote the green transformation of suppliers to create a low-carbon supply chain.

▶

Green Procurement: We give full consideration to factors such as environmental protection, resource conservation, recycling and low-carbon, prioritizing the sourcing

and utilization of energy-efficient, water-efficient, and material-efficient materials, products, and services under equal conditions. Furthermore, we proactively steer

suppliers towards establishing a sustainable value chain within the industry.

▶

Energy Saving and Consumption Reduction: We introduce advanced energy-saving technologies and equipment, promote packaging-free, green packaging and recyclable

materials, and improve overall supply chain energy efficiency.

(3)Conflict Minerals:

We strictly adhere to the UN Global Compact, OECD’s Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas, the

Responsible Minerals Initiative (RMI), as well as other international conventions and industry initiatives. We procure mineral raw materials conscientiously, striving to ensure

that all raw materials for our products are sourced in an appropriate manner. We actively promote suppliers to complete the CMRT Conflict Minerals Questionnaire while

consistently carrying out the Company's responsible sourcing program.

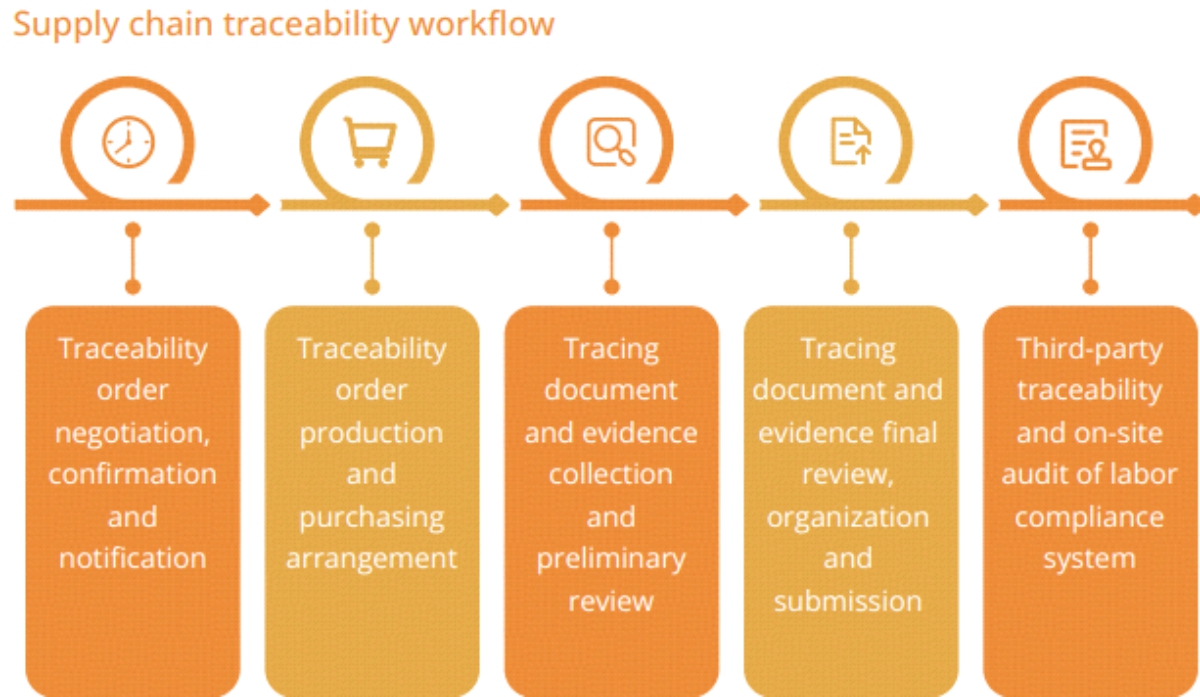

(4)Procurement Traceability:

Establish an end-to-end, full-process supply chain traceability system from silicon, wafers, cells to modules.

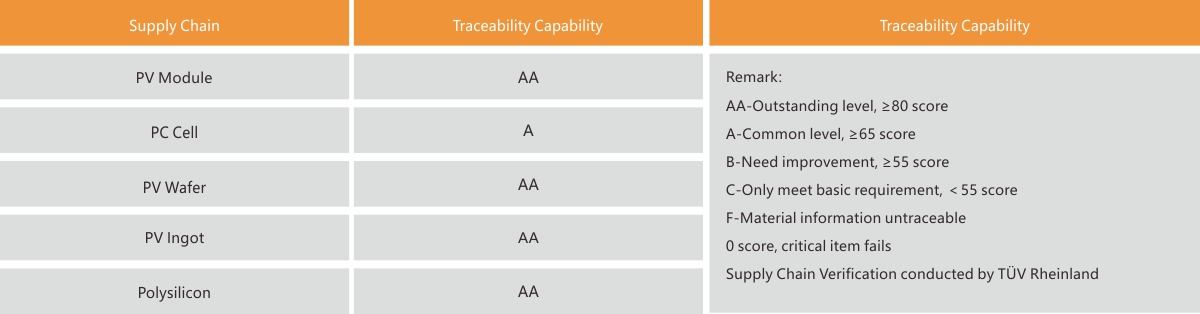

Tongwei’s tracing methodology/capabilities have been verified by independent third-party entities such as STS, TÜV Rheinland, etc. According to the Supply Chain Verification

conducted by TÜV Rheinland, the sectors of Module, Wafer, Ingot, and Polysilicon have attained AA ratings respectively, and sector of Cell has attained an A rating.

Tongwei’s tracing methodology/capabilities have been verified by independent third-party entities such as STS, TÜV Rheinland, etc. According to the Supply Chain Verification

conducted by TÜV Rheinland, the sectors of Module, Wafer, Ingot, and Polysilicon have attained AA ratings respectively, and the sector of Cell has attained an A rating.

Link: Tongwei Co., Ltd. Supplier Code of Conduct

Link: Tongwei Co., Ltd. Conflict Minerals Commitment and Policy

Link: Tongwei Traceable, Responsible and Sustainable Supply Chain Management

Link: Supply Chain Verification Report

Tongwei adheres to the management philosophy of "effective management hinges on personnel selection" and places significant emphasis on holistic talent development. Over

the years, we are committed to establishing a diverse, inclusive, healthy, and safe work environment to uphold the fundamental rights and well-being of employees, fostering

their continuous growth, and pursuing mutual advancement for both the organization and workforce.

(1) Talent Pipeline Development Strategy

Tongwei advocates an employment program based on the principles of "Value the capable ones, replace the mediocre ones, and dismiss the incapable ones". The Company

prioritizes evaluations that focus on abilities, performance, and character, and employs a merit-based approach in personnel appointments, disregarding seniority.

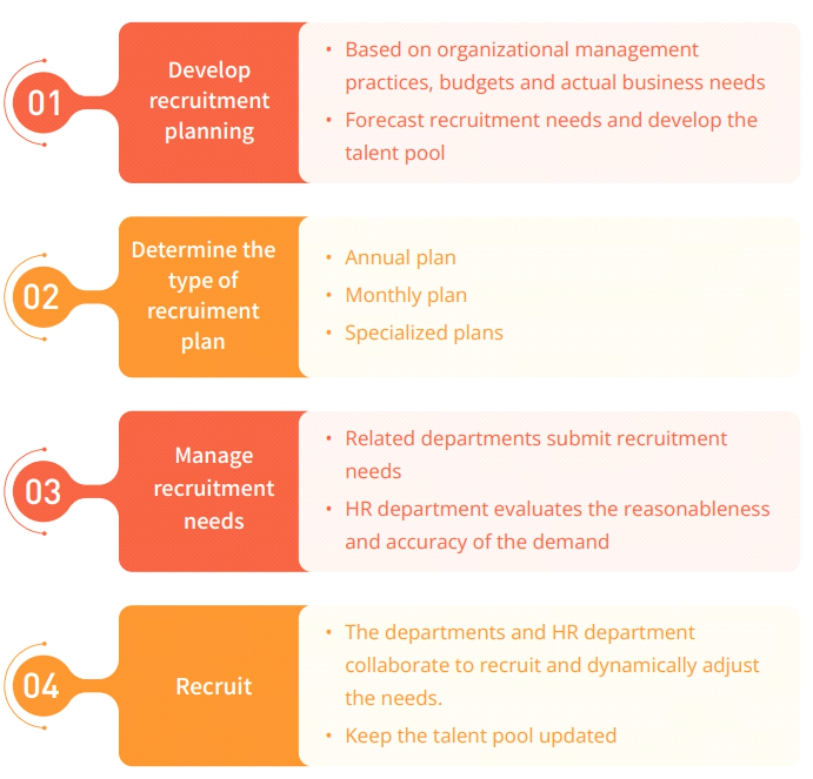

Tongwei consistently strengthens the talent attraction plan, formulates employee recruitment plans every year according to the company's business development needs and

changes in the talent market, strengthens the construction of the workforce, reserves talents for the company's development, and ensures the stability and vitality of the workforce.

(2) Talent Development and Growth Program

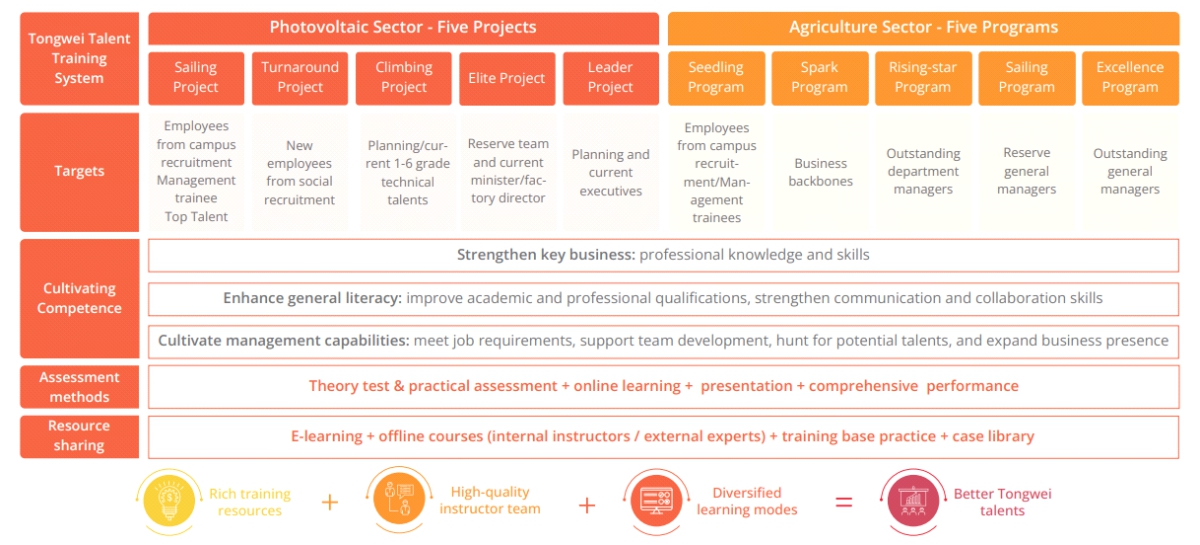

Tongwei has formulated a comprehensive, diverse and hierarchical talent training system for all employees, including the "Five Projects", "Five Programs", specific vocational

qualification training, academic education programs and many other programs, which help all employees continuously improve their professional skills and broaden their career

development paths to achieve comprehensive personal growth.

p class="row-info-t bold m-t-50">(2) Talent Development and Growth Program

Tongwei has formulated a comprehensive, diverse and hierarchical talent training system for all employees, including the "Five Projects", "Five Programs", specific vocational

qualification training, academic education programs and many other programs, which help all employees continuously improve their professional skills and broaden their career

development paths to achieve comprehensive personal growth.

Graduate Traineeship Program

Applicable Objects: Employees from campus recruitment, management trainees, Top Talents

Content of the Program:

Based on the "Five Projects" and "Five Programs", the "Sailing Project" and "Seedling Program" have been set up in the photovoltaic sector and the agricultural and animal

husbandry sector respectively. ". The two projects and programs target employees from campus recruitment, management trainees and top talents, and integrate a variety

of online and offline training resources to carry out training in professional business skills, comprehensive quality and management ability, and are committed to cultivating

young talents with potential.

In the photovoltaic sector, we have established a training channel for management trainees, and each year we select a group of promising "Top Talents" from the Sailing

Project participants to carry out a five-year comprehensive training. In the agriculture and animal husbandry sector, management trainees, fresh graduates and interns

will be integrated into a one-year seedling program for collective training.

Leadership Training Program

Applicable Objects: Planning and current executives, outstanding department managers, reserve general managers, outstanding general managers

Content of the Program:

Based on the "Five Projects" and "Five Programs", the Company has set up the "Elite Project" and "Leader Project" in the photovoltaic sector, and the Rising-star Program”,

“Sailing Program” and “Excellence Program” in the agricultural and animal husbandry sector. These projects and programs are aimed at building a core leadership team

with traction and impetus, and nurturing potential leaders

Job-specific Development Program

Applicable Objects: Planning/current 1-6 grade technical talents, Business backbones

Content of the Program:

Among the "Five Major Projects" and "Five Major Programs", the "Climbing Project" and "Spark Program" are set up to utilize various training resources and assessment

methods to train the planning/current 1-6 grade technical talents of the PV sector and the business backbones of the agricultural and animal husbandry sector.

Academic Education and Certifications Program

Applicable Objects: All employees (including contract and part-time employees1)

Content of the Program:

The Company has developed and implemented the Employee Self-Development and Training Management Measures of Tongwei Co., Ltd. to motivate employees to acquire

relevant vocational certifications or enhance their academic credentials. The policy outlines the reimbursement details for academic advancement expenses and subsidies

for certification attainment. Employees receive varying study grants based on their ranks, ranging from 1,000 yuan to 20,000 yuan annually per person, including:

- Academic education: obtaining a state-recognized undergraduate degree (or above) of higher education, with both a diploma and a degree certificate; the Company will

grant tuition reimbursement subsidies.

- Training for middle-level and senior titles: obtaining middle-level and senior titles (including vocational qualifications and technical titles) recognized nationwide through

relevant training; the Company will grant incentives.

- Expatriate training and learning: Expatriate training related to the job position; the Company will reimburse training expenses.

Outcomes of the Program (2023):

In 2023, the Company supported employees in improving their education and professional qualifications to the tune of 980,000 yuan; 886 employees received related

reimbursements and incentives.

College-Enterprise Partnership Program

Applicable Objects: All employees

Content of the Program:

Tongwei has forged profound partnerships with esteemed academic institutions such as Fudan University, Sichuan Agricultural University, Huazhong Agricultural University,

Jilin Agricultural University, and other premier domestic colleges and research organizations. These collaborations extend across technology research, talent cultivation,

skills training, and employment recommendations. Through initiatives like the "Tongwei Class," "Tongwei Elite Training Camp," and "Vocational Training Camp," a strategic

cooperation framework has been established at three key educational levels: Doctor's and Master's, Bachelor's, vocational and technical programs.

Outcomes of the Program (2023):

In 2023, the Company collaborated with multiple training institutions and higher education institutions to carry out more than 10 training courses and projects.

(3) Performance Appraisals and Feedback Processes

Tongwei prioritizes talent retention and promotion by emphasizing clear career development pathways, implementing a robust performance incentive system, and continually

enhancing internal competition and rotation mechanisms to facilitate employee growth and progression.

Performance Management Mechanisms:

We conduct regular quarterly and annual appraisals through performance management mechanisms such as indicator formulation, assessment methodologies,

feedback mechanisms, and complaint procedures, which serves as the foundation for salary distribution, talent promotion, and talent development.

Talent Promotion Procedure:

Tongwei has established the Position Promotion Management Procedures and the Cadre Development Management Procedures to standardize employee promotion and

advancement processes. According to the requirements of the position and the development path of career planning, we categorize employee career paths into six major

sequences: management, research and development, technology, function, marketing, and operation, so as to facilitate both horizontal and vertical advancement

opportunities, ensuring employees across all sequences have a transparent, unhindered, and equitable path to career promotion.

Internal Competitive Promotion

In order to motivate employees to continuously improve their professional skills and broaden their career opportunities, Tongwei provides a standardized and transparent

internal recruitment process, establishes a fair and unbiased assessment mechanism, and introduces policy support to attract talents aligned with corporate culture and

suitable for the positions.

Commendation and Incentive

To promote the outstanding corporate culture and unleash the enthusiasm and creativity of employees, Tongwei has formulated the Tongwei Co., Ltd. Employee Reward and

Punishment Policy, which clearly defines the circumstances of rewarding the employees with outstanding performances (including: praise, commendation, merit, great merit,

and special contribution awards), and stipulates the corresponding standards of rewards and commendations. For employees who have received awards, the relevant award

information will be recorded in their personnel files and prioritized for appointment, promotion and advancement.

In 2023, the company honored outstanding employees and teams of the year, with more than 1,500 people honored and nearly 10 million yuan awarded.

Case:In 2023, Tongwei Food held the 2023 Annual Summary and 2024 Work Plan Meeting. Tongwei Food honored the outstanding teams and employees of 2023. Every

striving member of Tongwei was honored with applause, inspiring more individuals to follow their example, boldly embrace challenges, and persevere courageously.

(4) Employee Welfare System

Tongwei attaches great importance to the job satisfaction and happiness of its employees, and has established a comprehensive employee welfare system and continuously

enriched its diversified welfare programs. We actively provide compensation and benefits covering all employees as well as non-compensation safeguards, which include statutory

social benefits, Tongwei exclusive benefits, employee mutual aid programs, and employee care programs.

Compensation and Benefits

Applicable Objects: All employees

Content of the Program:

· Insurance and housing fund: medical insurance, endowment insurance, unemployment insurance, insurance against injuries at work, maternity

insurance, housing fund

· Supplementary insurance: commercial accident insurance

Outcomes of the Program (2023):

· In 2023, Tongwei ensured that all employees were covered by 100% social security contributions; the percentage of all employees covered by supplementary insurance

(commercial accident insurance) is 100%.

Non-salary Benefits

Statutory social welfare

Applicable Objects: All employees

Content of the Program:

· Paid Leave: statutory holidays, annual leave, sick leave, marriage leave, maternity leave, breastfeeding leave, etc.

· Labor Protection: occupational health check, high-temperature subsidy

Tongwei-exclusive Welfare

Applicable Objects: All employees

Content of the Program:

· Life Care Amenities: welfare canteen, refreshments, personalized uniforms, holiday and care gifts, care mutual fund, and retirement support, etc.

· Family Visit Benefits: family visit vacation, travel expense reimbursement, etc.

· Health Protection: health checkup, insurance against accidental injury, etc.

· Loyal Employee Rewards: trophies and commemorative bonuses for employees who have completed 10 years of continuous service

· Incentive Perks: opportunities for studying abroad, travel, development training, etc.

Employee Care Program

Applicable Objects: All employees

Content of the Program:

· The Company has established the Employee Care Fund. Participation in the fund is voluntary, and the purpose is to facilitate mutual assistance. The fund will be used for the

subsidization of medical expenses of the employees, their spouses, parents and children, and for the condolence money for the employees' children.

Outcomes of the Program (2023):

· In 2023, the Employee Care Fund has audited 752 times and disbursed over 2.21 million yuan, caring for 730 employees.

Employee Support Program

Applicable Objects: All employees

Content of the Program:

· Recreational and Sports Activities:

- Sports competitions: badminton and basketball matches, etc.

- Social events: fun sports games, employee birthday parties, family days, holiday-themed activities, and culture-themed months, etc.

- Employees interest groups: badminton, yoga, dessert making, and other interests

Mental Health Care Program: the Company established an “emotional relaxing room”, and sought to reduce workplace stress among employees and improve their ability

to manage both physical and mental well-being through regular mental health activities such as sand tray games, on-site and online lectures, one-on-one psychological

counseling, interactive sessions, and health clinics.

Outcomes of the Program (2023):

In 2023, the Company continued to promote the improvement of the psychological counseling and mediation room, and carried out 9 psychological lectures at the Shuangliu

base, with more than 900 offline participants, while the Jintang base organized 4 large-scale mental health lectures with a total of more than 320 participants.

(5) Employee Satisfaction Survey and Grievance Reporting Mechanisms

Employee Satisfaction Survey

Applicable Objects: All employees

Frequency of the survey: conducted annually and on time

Content of the survey:

Tongwei places emphasis on gauging employee satisfaction concerning the Company's developmental status, managerial support, staff training and development

opportunities, teamwork dynamics, employee retention, and occupational health and safety measures. The Company devises enhancement initiatives aimed at continuously

augmenting the capacity to effectively manage and support workforce and fostering a deeper sense of belonging and loyalty among employees.

Outcomes of the Survey (2023):

In 2023, the job satisfaction survey at Tongwei covered all employees with an average participation rate of 90% and an overall satisfaction rate of 92%.

Employee Grievance Reporting and Escalation Procedures

Applicable Objects: All employees

Content of the procedure:

Tongwei has formulated a formal Employee Suggestions and Complaint Management Measures to provide employees with complaint policy support, a comprehensive

complaint mechanism, and a smooth complaint reporting channel, as a means of encouraging and welcoming employees to make suggestions and to supervise and

complain about inappropriate incidents.

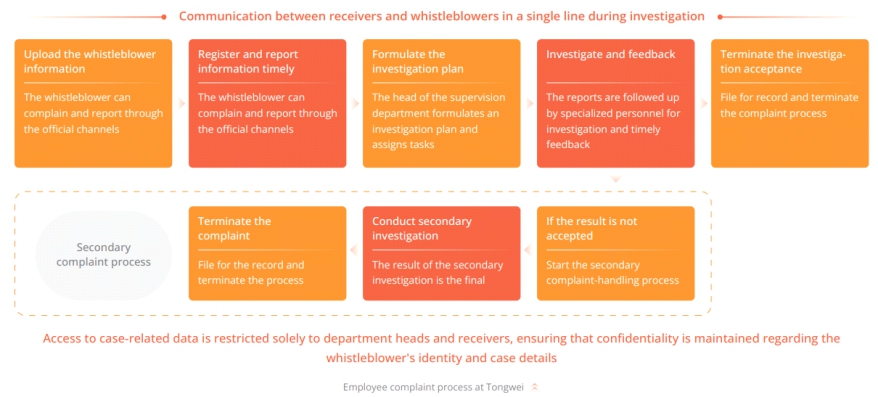

· Standardized process for employee grievances: Main steps including uploading reporting information, registering and filling in reporting information, formulating an

investigation plan, carrying out investigations and providing feedback, accepting the results of investigations, and terminating the process; whistleblowers have a single

line of direct contact with the receivers and can initiate a second grievance if they are not satisfied with the results of the first grievance.

· Scope of employee suggestions and complaints:

constructive and feasible opinions and suggestions on the existing process system, existing problems and hidden dangers;

complaints on the unjust and unfair treatment encountered by the employees themselves, as well as the violation of disciplinary behavior of employees at all levels of the

Company.

· Various channels are available for lodging complaints, including telephone, official account, email, and suggestion box. Information on relevant channels is disclosed in

Tongwei's ESG report, official website and official account.

Complaint and Reporting Channel at Tongwei

Tel: 028-86168834/86168838

Tel: 028-86168834/86168838

Mobile: 15608175053(also Wechat account number)

Mobile: 15608175053(also Wechat account number)

E-mail: jcb@tongwei.com

E-mail: jcb@tongwei.com

Address: 38th floor, Tongwei International Center, No.588 Tianfu Avenue, Hi-Tech Zone, Chengdu, Sichuan Province, 610095, China

Address: 38th floor, Tongwei International Center, No.588 Tianfu Avenue, Hi-Tech Zone, Chengdu, Sichuan Province, 610095, China

Official Account: Tongwei Integrity

Official Account: Tongwei Integrity

Internal Account Number: Tongwei Supervision

Internal Account Number: Tongwei Supervision

· Procedural confidentiality:

We are committed to maintaining strict confidentiality of the complainant and their complaint details, requiring that the investigating contractor

have a single line of communication with the informant, and that the relevant information about the case is known only to the head of the department and the contractor.

Furthermore, we guarantee the timeliness of the verification and investigation work, and undertake to take the necessary means to protect the personal safety and legitimate

rights and interests of the complainant when appropriate.