Efficiency Concerns

Efficiency is a crucial aspect when evaluating solar panels, and it directly impacts the panel's ability to convert sunlight into electricity. For polycrystalline solar panels, several factors determine their efficiency, setting them apart from their monocrystalline counterparts.

Comparison of Efficiency: Polycrystalline vs. Monocrystalline

Polycrystalline and monocrystalline solar panels have distinct differences in efficiency. Monocrystalline panels, made from a single crystal structure, generally offer higher efficiency, typically around 15-20%. On the other hand, polycrystalline panels, composed of multiple crystal fragments, usually have lower efficiencies, ranging from 13-16%.

The efficiency of a solar panel determines how much power it can generate per unit area. For example, a 200 watt polycrystalline panel might require more space compared to a monocrystalline panel of the same power output. This difference is vital for installations where space is limited, such as on residential rooftops.

Factors Affecting the Efficiency of Polycrystalline Panels

Several key factors affect the efficiency of polycrystalline solar panels:

- Material Quality: The purity of silicon used in polycrystalline panels is typically lower than that in monocrystalline panels. This difference in material quality can result in a slight decrease in efficiency.

- Temperature Coefficient: Polycrystalline panels often have a higher temperature coefficient than monocrystalline panels. This means they might lose more efficiency on hot days. For example, a panel with a -0.5% per degree Celsius temperature coefficient will lose 5% of its efficiency for every 10 degrees above 25°C.

- Manufacturing Process: The process of creating polycrystalline silicon is generally simpler and less costly, which can affect the quality and efficiency of the final product. However, advancements in manufacturing techniques are continually improving the efficiency of polycrystalline panels.

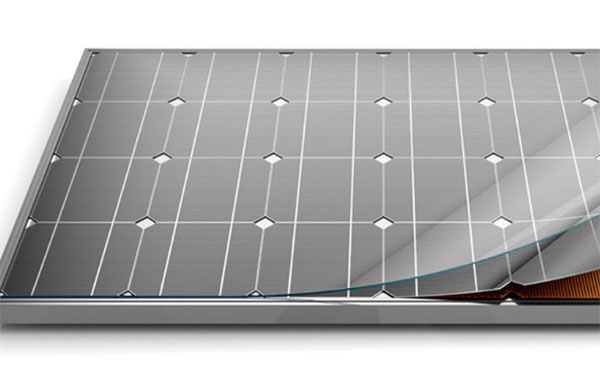

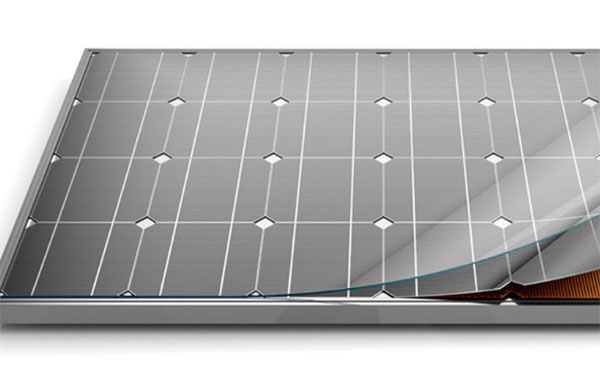

- Panel Design and Construction: The design, including the arrangement of silicon cells within the panel, can impact efficiency. Panels with a more optimized design can achieve higher efficiency rates within the typical range for polycrystalline panels.

- Incidence Angle of Sunlight: The angle at which sunlight hits the panel affects its efficiency. Polycrystalline panels may be slightly less efficient in capturing light at lower angles compared to monocrystalline panels.

In summary, while polycrystalline solar panels offer a more budget-friendly option, their efficiency is generally lower compared to monocrystalline panels. This efficiency trade-off must be considered alongside factors such as installation space, climate, and energy requirements. For more detailed technical information, the

Wikipedia page on Solar Panel Efficiency offers an in-depth look into the various aspects influencing solar panel performance.

Durability and Longevity

Durability and longevity are key considerations in the selection of solar panels. These factors determine how well the panels withstand environmental conditions and the duration of their effective operational life. In the case of polycrystalline solar panels, these attributes are influenced by several aspects, including material composition, manufacturing quality, and environmental exposure.

Lifespan Comparisons Among Solar Panel Types

| Solar Panel Type |

Average Lifespan |

Key Features |

| Polycrystalline |

25-30 years |

Made from multiple silicon crystals; slightly less efficient but cost-effective |

| Monocrystalline |

25-35 years |

Composed of a single crystal structure; higher efficiency, more expensive |

| Thin-Film |

15-25 years |

Made from various materials like amorphous silicon; flexible, less durable |

The lifespan of solar panels is a crucial aspect of their value proposition. Polycrystalline panels, while slightly less efficient than monocrystalline panels, offer a competitive lifespan, making them a viable option for long-term energy generation. The durability of these panels often correlates with the quality of materials used and the rigor of the manufacturing process.

Environmental Factors Influencing Polycrystalline Panel Durability

- Temperature Extremes: Polycrystalline panels are generally resistant to temperature variations. However, extreme temperature fluctuations can accelerate the aging process, potentially reducing their lifespan.

- Wind and Hail: The panels are designed to withstand moderate to high wind speeds and hail impacts. The resilience to such conditions depends on the panel's build quality and mounting system.

- Snow and Ice: Heavy snowfall and ice can stress the structural integrity of the panels. Proper installation and occasional cleaning can mitigate these effects.

- Sun Exposure: Constant exposure to sunlight can lead to material degradation over time. Polycrystalline panels are equipped to handle prolonged sun exposure, but their efficiency might decrease marginally with age.

- Moisture and Humidity: High levels of moisture can affect the panel's electrical components. Quality encapsulation methods are used to protect against moisture ingress.

- Pollution and Dust: Accumulation of dust and pollutants can reduce the efficiency of solar panels. Regular cleaning and maintenance are necessary to maintain their performance.

The durability and longevity of polycrystalline solar panels are influenced by a combination of material quality, environmental exposure, and maintenance practices. With proper installation and upkeep, these panels can provide a reliable source of renewable energy for decades. For a comprehensive understanding of solar panel durability, the

Wikipedia page on Solar Panel Longevity offers valuable insights.

Temperature Sensitivity

Temperature sensitivity is a critical factor in the performance of solar panels. Polycrystalline solar panels, like all photovoltaic systems, experience changes in efficiency and output when exposed to varying temperature conditions.

Performance in High-Temperature Environments

Polycrystalline solar panels generally experience a decrease in efficiency as temperature rises. The standard measure for this change is the temperature coefficient, usually expressed as a percentage decrease in output per degree Celsius increase in temperature. For instance, a typical polycrystalline solar panel might have a temperature coefficient of around -0.4% to -0.5% per °C. This means that for every degree above 25°C (77°F), the panel’s efficiency decreases by 0.4% to 0.5%.

The impact of high temperatures on polycrystalline panels is significant, especially in hot climates. For example, in an environment where the temperature regularly reaches 35°C (95°F), a polycrystalline panel could see its efficiency reduced by up to 4% to 5% from its rated capacity.

Comparative Analysis with Other Panel Types

When comparing polycrystalline solar panels to other types, such as monocrystalline and thin-film, differences in temperature sensitivity become apparent:

- Monocrystalline Panels: These panels typically have a slightly better temperature coefficient, usually around -0.3% to -0.4% per °C. This means they are a bit more efficient than polycrystalline panels in high-temperature environments.

- Thin-Film Panels: Thin-film technology, which includes amorphous silicon, CdTe, and CIGS panels, often has better temperature coefficients, sometimes as low as -0.2% per °C. However, they generally have lower overall efficiency compared to crystalline silicon panels.

- Performance Comparison: At higher temperatures, monocrystalline panels tend to maintain better efficiency than polycrystalline panels. Thin-film panels exhibit the least temperature sensitivity but compensate with lower baseline efficiency.

In summary, while polycrystalline solar panels are an economical choice, their efficiency can be more adversely affected by high temperatures compared to monocrystalline or thin-film panels. This trade-off must be considered in the context of the specific environmental conditions and energy needs of the installation site. For more detailed information on this topic, the

Wikipedia page on Photovoltaic System Performance provides an in-depth look at the factors influencing solar panel efficiency under various conditions.

Cost vs. Performance Analysis

The balance between cost and performance is a pivotal aspect in the decision-making process for solar panel installation. Polycrystalline solar panels, known for their relatively lower cost compared to monocrystalline panels, offer a different value proposition in terms of performance and return on investment (ROI).

Initial Investment vs. Long-Term Gains

Polycrystalline panels typically have a lower upfront cost, with prices varying depending on the brand, size, and efficiency of the panels. For example, a standard polycrystalline solar panel system might cost between 10% to 20% less than a comparable monocrystalline system. This cost difference can be substantial, especially for larger installations.

Despite the lower initial investment, it's essential to consider the long-term gains. Polycrystalline panels usually have slightly lower efficiency rates, which means they generate less electricity over time compared to monocrystalline panels. This efficiency gap can translate to longer payback periods and potentially lower overall savings in the long run.

Comparing ROI of Polycrystalline Panels with Other Technologies

When comparing the ROI of polycrystalline panels to other solar technologies, several factors come into play:

- Efficiency: Polycrystalline panels typically have efficiencies ranging from 13% to 16%. In contrast, monocrystalline panels can reach efficiencies of up to 20%. Higher efficiency means more power generation and potentially greater savings.

- Lifespan: Both polycrystalline and monocrystalline panels generally offer similar lifespans of 25 to 30 years. However, the efficiency degradation rate over time may be slightly higher in polycrystalline panels.

- Energy Costs: The ROI also depends on local energy costs. In areas with high electricity prices, the quicker payback of more efficient (but more expensive) panels might justify the higher upfront cost.

- Installation Size and Conditions: For large-scale installations or installations in space-constrained areas, the higher efficiency of monocrystalline panels might be more beneficial despite the higher initial cost.

In conclusion, polycrystalline solar panels offer a more affordable entry point into solar energy but may result in lower efficiency and longer payback periods. The decision should consider both the immediate budget and the long-term financial and energy production goals. For an in-depth analysis of solar panel costs and returns, the

Wikipedia page on Photovoltaic System Economics provides valuable insights.

Environmental Impact

The environmental impact of solar panels, including polycrystalline types, extends beyond their clean energy production. It encompasses the entire lifecycle, from manufacturing to disposal, highlighting the importance of assessing their overall ecological footprint.

Manufacturing Process and Carbon Footprint

The manufacturing process of polycrystalline solar panels involves several steps that contribute to their carbon footprint. The key stages include:

- Silicon Extraction and Purification: This is an energy-intensive process, as it involves extracting silicon from quartz and purifying it for use in solar cells. This step significantly contributes to the carbon footprint of the panels.

- Panel Production: The production of the panels involves cutting silicon into wafers, assembling these wafers into cells, and then integrating these cells into the final panel. Each stage consumes energy and resources, adding to the environmental impact.

- Transportation: The carbon footprint also includes the transportation of materials and finished products, which depends on the distance and mode of transport.

Despite these factors, the overall carbon footprint of polycrystalline panels is often lower compared to fossil fuel energy sources. The

Wikipedia page on the Environmental Impact of Solar Power provides a comprehensive overview of the ecological aspects of solar energy.

Recyclability and Environmental Concerns

The end-of-life management of polycrystalline solar panels is crucial for minimizing their environmental impact. Key points include:

- Recyclability: Polycrystalline solar panels are recyclable, but the process is complex. It involves separating and recovering various materials like glass, silicon, and metals. Advances in recycling technology are making this process more efficient.

- Waste Management: Proper disposal is essential to prevent harmful materials from contaminating the environment. While solar panels contain some toxic materials, like lead in solder, the quantity is relatively small.

- Lifecycle Assessment: Considering the entire lifecycle, from manufacturing to disposal, polycrystalline solar panels have a significantly lower environmental impact compared to traditional energy sources.

- Innovation in Manufacturing: Ongoing research and innovation aim to reduce the environmental impact of solar panel production, focusing on more sustainable materials and energy-efficient manufacturing processes.

In summary, while the manufacturing and disposal of polycrystalline solar panels have some environmental implications, their overall impact is much lower compared to non-renewable energy sources. Continuous improvements in manufacturing efficiency and recycling technologies are further reducing this impact. For more details on the sustainability of solar energy, the

Wikipedia page on Sustainable Energy offers valuable insights into the broader context of environmental sustainability in energy production.

Installation and Maintenance Challenges

The installation and maintenance of polycrystalline solar panels involve a range of challenges, from the complexity of the setup to the ongoing requirements for ensuring optimal performance and longevity.

Complexity and Costs of Installation

The installation process of polycrystalline solar panels includes several steps that can influence the overall complexity and cost:

- Site Assessment: This involves evaluating the location for solar installation, considering factors like sunlight exposure, roof integrity, and space availability. The suitability of the site can significantly impact the installation process and costs.

- System Design and Planning: Designing a solar power system requires careful planning to optimize energy production. This includes selecting the appropriate size and number of panels, inverter type, and the layout of the installation.

- Installation Costs: The cost of installing polycrystalline solar panels can vary based on factors like system size, location, and labor rates. Generally, the installation costs can account for a significant portion of the total system price.

- Permitting and Regulations: Navigating the local permitting process and adhering to building codes and regulations can add complexity to the installation process.

Ongoing Maintenance Requirements

Once installed, polycrystalline solar panels require regular maintenance to maintain their efficiency and extend their lifespan:

- Cleaning: Panels need periodic cleaning to remove dust, dirt, and debris, which can block sunlight and reduce efficiency. The frequency of cleaning depends on the local environment.

- Inspections: Regular inspections help identify and address potential issues like loose connections, damage to the panels, or inverter problems.

- Performance Monitoring: Monitoring the system’s performance is crucial to ensure it operates at optimal efficiency. This can involve checking the energy output and comparing it to expected performance levels.

- Repairs and Replacements: Over time, components of the solar system may require repairs or replacements. This includes parts like inverters, connectors, and sometimes the panels themselves.

In conclusion, while the installation of polycrystalline solar panels presents certain challenges, proper planning and execution can mitigate these issues. Additionally, regular maintenance ensures the system continues to function efficiently over its lifespan. For more detailed information on solar panel installation and maintenance, the

Wikipedia page on Photovoltaic System provides an extensive overview of the technical and practical aspects involved.